I developed the following digram for the 1975 R107 Mercedes-Benz 450SL so I would have a complete guide should anything go wrong after the car is put back together. This digram does not show the engine vacuum.

LEAK DETECTION:

When diagnosing leaks in the Mercedes vacuum system, a vacuum pump with gauge is mandatory or should you have a smoke machine on hand, that would be the ultimate way to go.

First, start by checking the vacuum tanks for leaks. One is located directly under the front fender on the passenger side above the wheel (LHD). This tank supplies vacuum to the central locking system and cruise control. The other tank is located behind a panel to the left of the emergency brake. This one hold vacuum for the climate control.

|

| Unscrew plastic panel and slide away to expose tank. To remove tank and panel, e-brake assembly must be removed. |

|

| Passenger side U.S. model |

The vacuum tank for the climate control should not have any issue with deterioration other than the rubber grommet that seals the tank where the vacuum line enters. This part is still available through Mercedes.

The central locking vacuum tank however is susceptible to damage and deterioration as it is open to the elements just above the front wheel. Both the tank and grommet are still available from Mercedes.

A good test to perform to insure proper vacuum is maintained, is to pump up the tank down to 10 mHg. Make certain that your connections are leak free and your gauge is good. The tank should hold vacuum for at least 48 hours without any loss of vacuum. Conduct this test on both tanks. I personally would not recommend using the smoke machine to test the vacuum tanks.

Finding leaks in the system is not complicated, but time consuming. Most often it is the rubber connectors that dry rot and begin to leak. If you have the original system, it is best to test each section of vacuum line by disconnecting, capping and testing one section at a time. The digram will show how the system is divided up throughout the car.

Vacuum leaks are also very prevalent at the diaphragm type locking modules. At 40+ years, the rubber diaphragms are quite crispy and will likely leak. These include the heater tap, fresh air flaps at cowl, passenger side door, fuel flap, and trunk. The passenger side door lock, and trunk lock on earlier 450SL's are no longer available from Mercedes.

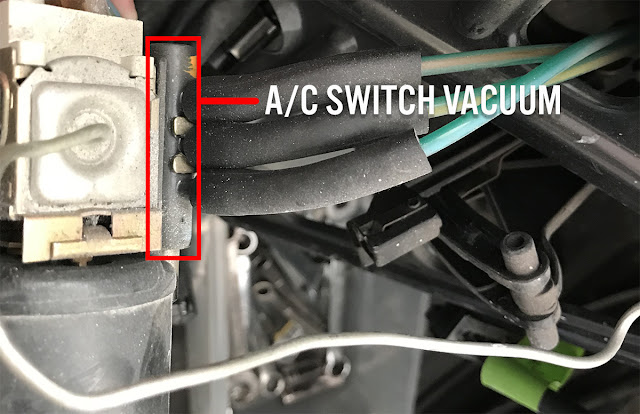

Other points of leakage are the driver door lock master vacuum switch and the vacuum switch at the A/C switch. Both switches are identical in function but are designed differently. Both are available from Mercedes.

The final potential point of a vacuum leak is the Ford-Philco cruise control unit. The cruise control unit is most likely under the dash behind the glove box on a U.S. car.

It is also wise to change out any check valves. They are located under the hood at the fire wall driver side. Original check valves are black and green while the new ones are blue and black. These are unmetered.

It is also wise to change out any check valves. They are located under the hood at the fire wall driver side. Original check valves are black and green while the new ones are blue and black. These are unmetered.