This article will cover the inspection and first phase in the restoration process of the Mercedes-Benz Bosch D-Jetronic wiring harness. There are several variations on this harness, so it should be noted the one used for this article is from a 1975 Mercedes 450SL.

If you have not yet removed the harness, see my article on the removal process, dated 3/30/17. The following steps are based on the wiring harness being removed from the car.

STEP 1

This process will take patience, time and scrutiny. Every inch of the harness should be examined for damaged harness covering, wiring and connectors.

More than likely the harness will be quite tattered and in need of a full strip down, but in the event there are sections in very good shape, they can be saved. I personally like to keep as much original material as I can and the harness is not acceptation.

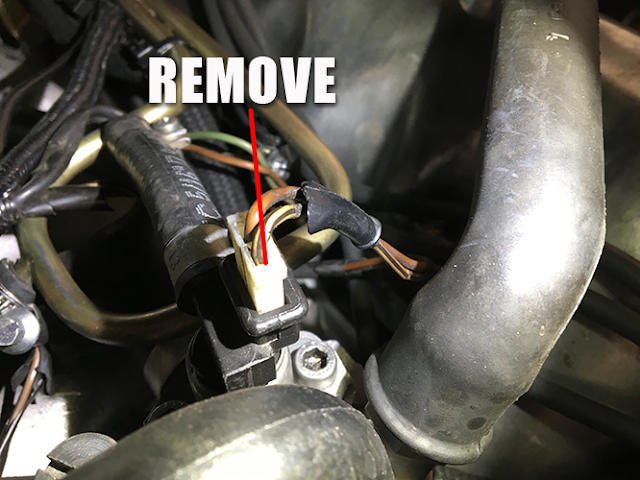

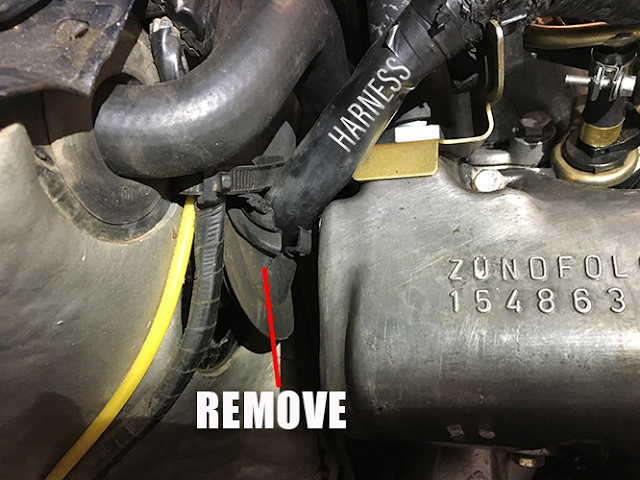

The following photos show the harness having just been removed from the car and the over all condition it was in.

STEP 2

Begin removing the old wire coverings one section at a time. It is a good idea to do one section at a time to keep things routed as close to factory as possible. By doing this you will keep everything plugging back in as it originally did with regard to lead length and positioning. I would recommend using a brand new X-Acto knife to very carefully remove the old harness covering that is bad. DO NOT PRESS TOO HARD TO AVOID SLICING THE WIRING BELOW.

STEP 3

Check all plugs for cracking and excessive yellowing of the plastic. In either case, it is highly advised to replace them. There are two options for the two pole connectors. The fist is a prewired two pole plug from BWD part No.27424 (only 2 pole are available) which would need to be soldered in line. Certainly this works, but is not nearly as professional and neat as option two. The other option, and a far better one than the first, is to purchase new spade connectors and corresponding plugs. Both the plugs and the spade connectors are available from Repro-Parts in Germany www.repro-parts.de in both 2,3,4 and 5 pole. This was the option I chose, and the quality is excellent. This company also produces all the terminal boots for Mercedes-Benz and Porsche. The photos below show the process of fitting a new BWD plug and fitting new spade connectors from Repro-Parts.

|

| BWD 2-pole plug ready for soldering to injector leads. |

|

| Spade connectors and new plug end from Repro-Parts. This particular plug is for the MPS |

STEP 4

Prep wires for spade connector as shown in photo above. Strip approximately .25 inches from each wire. Mercedes used 18 gauge wire for this particular 1975 harness. Twist each copper wire end to keep from fraying.

STEP 5

Using a ratcheting crimping tool fitted with an “open barrel” crimping die, insert spade as shown in photo below. This particular die crimps both segments of the spade simultaneously. NOTE: set pressure to lightest setting for this purpose.

|

| Pro'sKit crimping tool |

STEP 6

With spade connector in place, insert prepared wire making sure the insolation and the wire will be crimped in the appropriate places. Repeat as necessary. Photos below show initial steps and final product.

|

| Wire interred in to spade connector and ready for crimping. |

|

| Wires after crimping on spade connectors |

STEP 7

Using your original plug as a reference, insert spade connectors into new plug. Make sure you insert wires into the correct port. Also make sure each connector clicks in place.

|

| Use old plug as reference |

|

| Wires fitted to new plug |

STEP 8

Finish by trimming any excess shrink tubing and pull boot over plug.

COMING UP...

In the next article, we will cover checking and repairing the numerous other plug styles that make up the remaining harness.