Now is also a good time to check brake pads for wear and also the calipers for any leaks. As our cars approach over 40 years, things will need to be replaced and things will begin to leak and obviously brakes are not something to neglect.

This article will cover removing the rear rotors and calipers and an inspection along the way.

STEP 1

Jack up car and remove rear wheels.

STEP 2

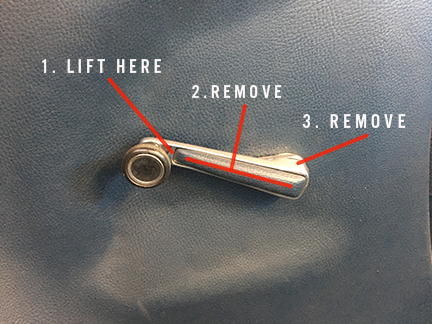

Prepare to remove the rear calipers. Make sure emergency brake is DISENGAGED. Pry open lock tabs with a screwdriver. These will need to be replaced as they will most likely be significantly weakened and will not stand up to reinstallation. They are still available from Mercedes-Benz.

STEP 3

Tap out (remove) the locking pins, and remove spring. If the hardware is in good shape it can easily be cleaned up using a bench top wire wheel. Should it need to be replaced, it is available from Mercedes-Benz and many aftermarket Mercedes parts shops.

STEP 4

When hardware is removed remove brake pad, depress caliper pistons using channel lock pliers as shown. When pistons are sufficiently depressed, the pad should slide out very easily.

STEP 5

Loosen bolts with a 19mm socket attached to a breaker bar. If car has been exposed to particularly wet or salty conditions a good soaking of penetrating oil the day before would be recommended. Once the two bolts have been removed the caliper will fall off if not held in place. These bolts should not be reused.

Hang caliper so it does not hang from flexible brake line hose. At this stage make sure the hoses are in excellent condition. If there is any cracking or feeling of dryness, REPLACE THEM! Also, check the condition of the pads. If your hoses will need replacing I will be doing an article on brake bleeding shortly.

STEP 7

Check rotors for deep scoring or warping and replace if necessary.

STEP 8

Remove rotors. Begin by lightly tapping all round hub and lightly around rotor surface on front. If that does not release the rotor, tap firmly on back where caliper was located. IF you are replacing the rotors and emergency brake shoes a penetrating oil can be sprayed inside each of the lug bolt holes to help release any rust that may hold the rotor from releasing. REMEMBER any grease will foul the operation of the braking systems.

STEP 9

Inspect emergency brake (each side) for wear, corrosion, and be sure it is fully releasing and engaging. If new emergency brakes are needed they are available through Mercedes-Benz. The kit provides all the necessary hardware and shoes for both sides. A future article will cover emergency brake replacement. In my case I am replacing the e-brakes.

| Mercedes R107 Emergency Brake. Appears to be original and never touched. Needs to be replaced. |

STEP 10

Installation is in reverse order. Be sure that all braking surfaces are 100% free from any oil or greases before installation. Unfortunately my rear calipers were rusting in the piston cylinders and so I needed new ATE calipers, and discs. ATE calipers are available new from aftermarket Mercedes parts stores or from Mercedes-Benz. If you need just the piston they are available from Mercedes-Benz.

NOTE: When reinstalling caliper hardware, be sure to properly lubricate all components with applicable caliper grease.

| Complete and ready for bleeding |

COMING UP

• Super Easy One Person Brake Bleeding

• Replacing Emergancy Brake

• Rebuilding ATE Brake Caliper

...and much more