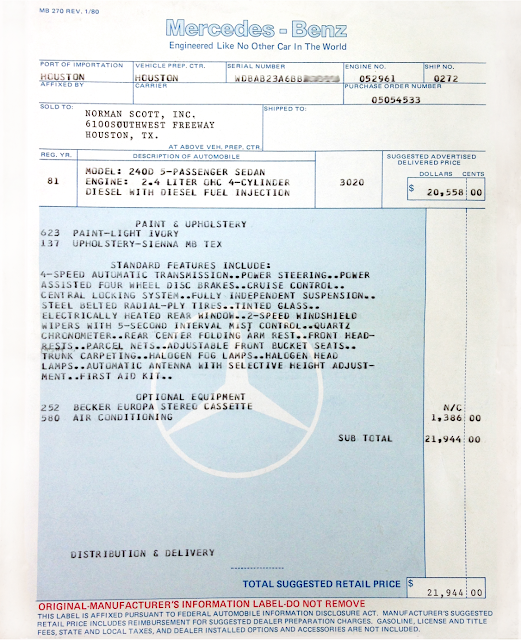

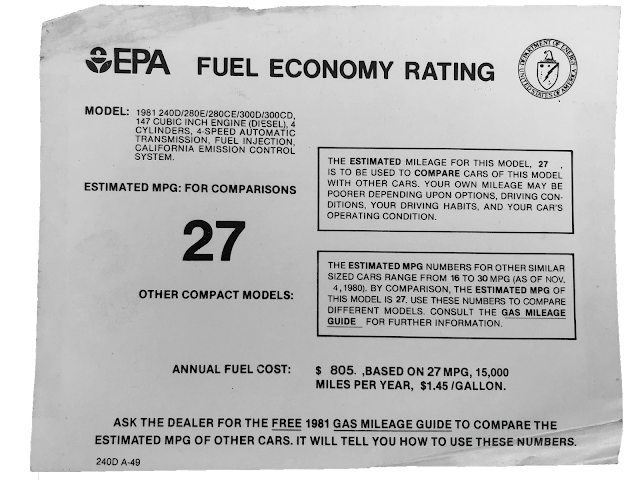

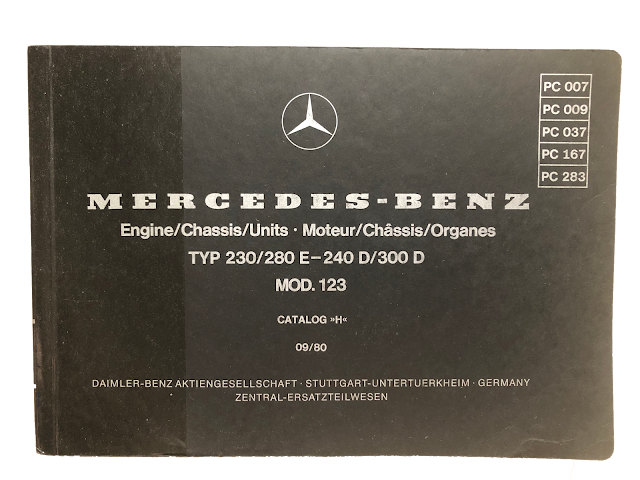

The work in this case is being performed on a 1981 Mercedes 240D - W123 (2nd generation steering column) and is also very similar in procedure as the early R107 and W123 series as well. Differences between Early R107 and W123 vs. later models is the set up of the steering column. Other models may be similar, but I advise you refer to the shop manual for the specific model for verification.

Again, there is much misguided information online for doing this job, however this is a very straightforward process that is listed in the Mercedes worship manual and does not require removing the steering box and also allows you to go through the and clean the steering shaft, bearings, etc.

As you will see, this does not take incredible skill or time to perform. It should take no more than 1hr. to perform this service. I always recommend taking photos as you go!

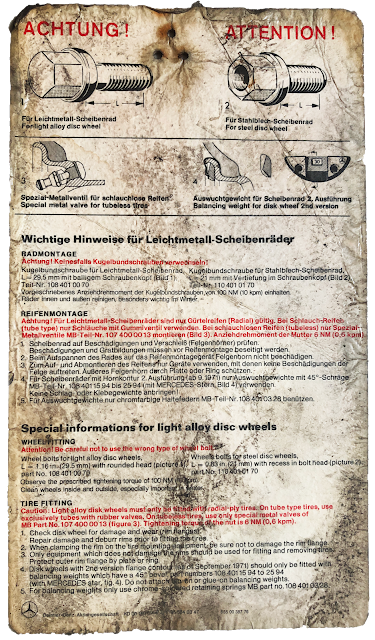

Recommend parts for the job: Mercedes-Benz steering coupler MB Part: 1234600210, two coupler bolts MB Part: 2029902101. I do not recommend reusing the original bolts. Steering column boot (at firewall) MB Part: 1234621396

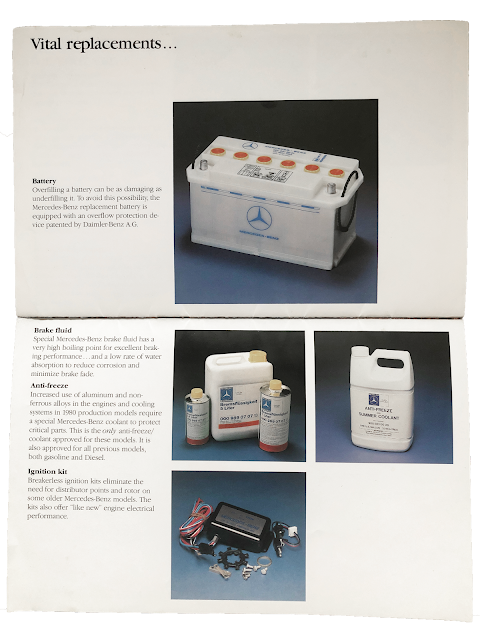

Optional Parts: steering column bearing MB part: 1269810025, directly behind steering wheel. My bearing had been making noise and discovered it was full of dirt. This may be more of an issue due to the car having spent its entire existence in the desert. There is also another identical bearing at the opposite end of the steering column tube, but mind was not acting suspicious and so I just sprayed lube into the bearing area.Regardless, it may be a good time to re-lubricate it. I use Würth greases for hinges and fittings such as this along with the throttle linkage which should be lubricated yearly.

STEP 1

Disconnect Battery

STEP 2

Remove driver side under dash covering.

STEP 3

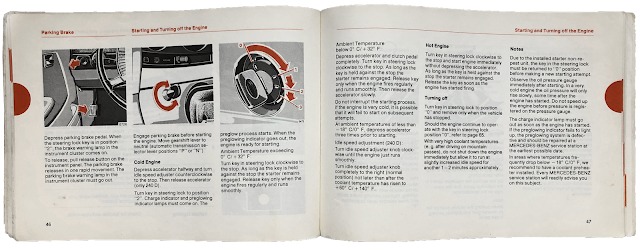

Center wheels, this is not critical on removal but will have to be done on reassembly. Remove steering wheel emblem or horn pad, which ever is less destructive to the old materials. Always go gently and do not use a screwdriver. Only use plastic trim removal tools.

STEP 4

Remove steering wheel hex cap screw or nut and remove steering wheel. The hex bit socket should be 10mm. Always make sure the socket for either the nut or the screw the perfect fit and is fully stetted. IMPORTANT: Do Not use the steering wheel lock for the resistance needed to remove the steering wheel hex socket screw, or nut. Unlock the steering column by means of your key and be sure it is fully unlocked before proceeding.

|

| Shown on W123 late model |

STEP 5

Remove rubber multi-stalk control boot at column. Gently pry off with plastic trim removal tool.

STEP 6

Unscrew multi-stalk controls from column in addition to the horn contacts (1 brown, 1 black wire)

STEP 7

Unplug turn signal stalk and cruise control (if equipped) from underside of dash to left of steering column.

STEP 8

Gently work wires and plugs through steering column. While it all looks like too much to come through, it will, but it's a snug fit. Don't yank as you can break solder connections in plug. Once the unit has been removed from the steering column notice the exact position of the steering shaft. The steering shaft is in the correct position when the shaft locks into position with the key out of the ignition. THIS STEP IS IMPORTANT for reassembly to ensure the steering wheel locks when car is parked and to ensure turn signal will cancel and remain on at the proper times.

STEP 9

Remove decretive column cover. This step is not necessary, but since I was in it this far I decided to remove two screws and detach the short plastic column cover for cleaning. You will however need to remove snap ring around steering shaft.

STEP 10

Put steering wheel back on shaft, but do not bolt on. Open the hood to access the steering coupler (rag joint).

STEP 11

The two hex cap screws are located adjacent to each other with the two screws facing opposite directions. This will require the steering wheel to be turned slightly to access both screws. Again, DO NOT strip these hex socket screws. If the car has lived in a humid/winter environment soak liberally with PB blaster or similar 3-4 hours prior to removing. It is strongly advised to use air impact tools for removal to reduce the chance of stripping the head.

STEP 12

Return to inside of car and undo hex socket screw from the second coupler under the dash. The steering wheel may need to be rotated a bit to access the screw. Once the screw is accessible, remove using a socket wrench. This one is not going to be seized unless it has gotten wet. Once removed, turn the steering wheel a few inches left and right to loosen the interior coupling.

STEP 13

Remove steering wheel.

STEP 14

From inside of car, remove steering column boot and press toward the engine bay. More than likely this boot will be very dry rotted and will need replacing. The part is available from Mercedes-Benz.

STEP 15

At this time you will also jack up the front of the car and place jack stands at the proper jack points. Remove driver side wheel and remove the three bolts holding the steering box to the fender. NOTE: I found this to work best with two people to make sure the steering box did not shift to suddenly. The steering box will sit in place once released. To make room to easily remove the steering coupler, simply move the steering box toward the front fo the car about 1-2 in. or 2.54 - 5.08cm. You will need someone to also help you bolt the steering box back into position once the new coupler has been installed.

STEP 16

With a suitable long handled flat end pry bar, loosen steering coupling by gently pressing toward firewall. Once the coupler is mostly released from the splined steering box shaft, you may need to return to the side of the car to gently wiggle the crush tube portion of the steering column away from the main steering shaft. I discovered a few back and forth trips, between wiggling the coupler and the crush tube loosened it up and the coupler and the crush tube easily separated.

STEP

At this point you are ready to install your new coupler, boot, and screws. IMPORTANT: When fitting the new coupler, it is critical that the steering shaft be properly aligned as described in STEP 8. In addition, the wheels need to be manually adjusted to straight ahead, or your steering will be off center. DO NOT, compensate adjusting your steering wheel installation for not having your wheels in the proper position. Steering coupler screws should be torqued to 25Nm.

Don't forget to put your new boot on before you affix the coupler.

STEP 18

MAKE SURE EVERY NUT, BOLT, SCREW AND SNAP RING IS PROPERLY FITTED! Take a test drive on side streets making plenty of turns etc. before going out on the highway. Check and recheck your work.

Optional Bearing Change

If you wish to change out the nearside steering shaft bearing it is indicated in the photo below.